Unlocking the Value of Thorough Welding Evaluation Providers for Building And Construction Projects

In the world of building tasks, the relevance of complete welding assessment solutions can not be overemphasized. Welding is an essential part in the construction process, crucial for the architectural honesty and security of any kind of towers. The real value of thorough welding assessment solutions lies not just in meeting governing requirements but additionally in making certain that the task's welds are performed to the highest possible requirements of top quality. By diving into the ins and outs of welding inspection solutions, one uncovers a globe where focus to information can make all the distinction in the long-lasting success of a building undertaking.

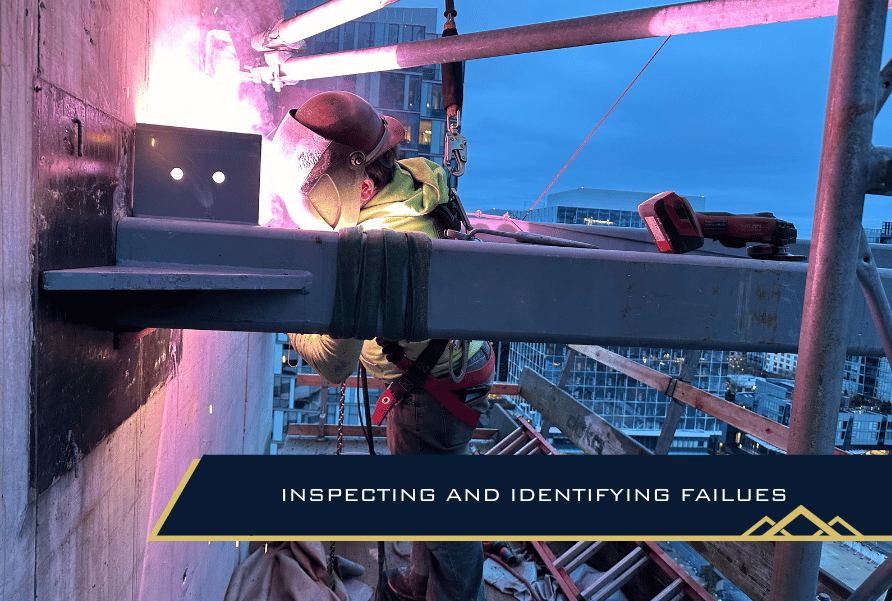

Significance of Welding Assessment Solutions

Welding assessment solutions play a vital function in guaranteeing the architectural integrity and safety and security of construction tasks. By diligently checking out welds for defects, adherence to requirements, and general top quality, these services help avoid prospective failings that might cause pricey rework, project hold-ups, or also disastrous mishaps. Welding evaluations are vital at various phases of a task, from first manufacture to final setting up, to confirm the honesty of important links and joints.

Additionally, welding evaluation services supply assurance to project stakeholders, including service providers, designers, and regulatory authorities, that welding procedures have actually been implemented correctly, adding to the total top quality and safety and security of the structure. In verdict, the value of welding inspection services can not be overstated in maintaining the integrity and longevity of construction tasks.

Cost-Effectiveness and Efficiency

Provided the important role that welding assessment services play in guaranteeing the structural stability and safety and security of building and construction tasks, it is necessary to evaluate the cost-effectiveness and effectiveness of these services in maintaining project quality. Cost-effectiveness in welding evaluation solutions refers to achieving the preferred level of top quality and security in construction projects at one of the most sensible cost. Effective welding evaluation solutions involve conducting examinations in a prompt fashion without compromising the thoroughness and accuracy of the evaluation.

Buying thorough welding examination solutions can cause long-lasting price savings by determining problems early in the building and construction process, protecting against rework, and avoiding pricey repair services or failings post-construction. Reliable evaluation procedures can help simplify project timelines, decrease downtime, and improve total performance on the building and construction website. By guaranteeing that welding is done appropriately the very first time, welding examination services add to preventing possible delays and guaranteeing that the task is finished on time and within budget. Inevitably, the cost-effectiveness and efficiency of welding examination solutions are integral to the success and toughness of building tasks.

Compliance With Market Standards

Following established industry requirements is extremely important in making certain the quality and security of welding evaluation solutions for building tasks. Compliance with these criteria warranties that the welding procedures are carried out in a manner that satisfies the specified demands, ultimately leading to structurally seem and sturdy building and constructions. Market standards offer clear guidelines on the appropriate strategies, materials, and devices to be made use of throughout welding examinations, making certain that completion results are of top quality and meet regulative expectations.

By adhering to industry standards, building and construction jobs can reduce threats related to welding flaws, such as fractures, insufficient infiltration, or inappropriate weld sizes. Non-compliance with these requirements can cause architectural failings, security dangers, and pricey rework. Therefore, it is vital for welding examination solutions to remain updated with the current sector standards and regulations to supply dependable and certified services to building and construction projects.

Enhancing Structural Honesty

Through non-destructive testing techniques such as ultrasonic testing, radiographic testing, and magnetic bit examination, welding inspectors can identify flaws that are not visible to the nude eye. This positive method permits prompt corrections to be made, stopping catastrophic failings and ensuring that the project exceeds or fulfills sector requirements for architectural stability.

Inevitably, buying detailed welding assessment services to improve structural stability is a cost-effective action that can conserve both time and money in the future. By prioritizing quality guarantee via you can look here strenuous inspection techniques, building and construction projects can attain optimal architectural efficiency and durability.

Long-Term Resilience and Safety

For building projects, achieving lasting resilience and safety is vital to ensuring the success and durability of the constructed framework. Welding plays an essential duty in the construction sector, and the top quality of welds straight impacts the general sturdiness and security of the job. Through thorough welding evaluation services, building and construction teams can determine potential weak points, flaws, and variances from design specifications that can endanger the framework's stability gradually.

Long-lasting toughness is important to minimize maintenance expenses, avoid architectural failures, and guarantee the safety and security of occupants - Welding Inspection Racine. By performing extensive welding examinations during the construction phase and occasionally throughout the framework's life expectancy, task supervisors can address issues proactively, implement needed repair services or reinforcements, and expand the structure's durability

Furthermore, making sure the security of the constructed environment is a lawful and ethical commitment for building and construction stakeholders. Welding inspections help identify prospective safety hazards such click for more info as splits, insufficient welds, or incorrect product combination that could bring about accidents or structural failures. Focusing on long-lasting sturdiness and safety and security through strenuous welding inspections is an essential element of liable building methods.

Final Thought

Finally, the value of thorough welding evaluation solutions for building and construction projects can not be overemphasized. By guaranteeing conformity with sector requirements, enhancing architectural honesty, and advertising lasting sturdiness and security, these solutions play a vital function in the success and durability of building and construction projects. Purchasing welding evaluation services is a effective and cost-efficient way to avoid potential issues and make certain the overall top quality of the project.

Furthermore, welding assessment solutions offer guarantee to project stakeholders, including service providers, engineers, and governing authorities, that welding procedures have been executed correctly, contributing to the total top quality and security of the structure. Welding Inspection Racine.Provided the important function that welding assessment solutions play in making sure the architectural stability and safety and security of building and construction jobs, it is necessary to evaluate the cost-effectiveness and effectiveness of these services in keeping task high quality. Reliable welding assessment solutions involve performing inspections in a timely way without jeopardizing the thoroughness and accuracy of the evaluation

By go now making certain that welding is done appropriately the first time, welding evaluation services contribute to making sure and avoiding possible hold-ups that the task is completed on schedule and within budget. Complete welding evaluation solutions play an essential role in this procedure by recognizing potential weak points, flaws, or mistakes in the welding procedure that could compromise the architectural integrity of the project.